Hello!

It’s been a while, hasn’t it…something like two years and a

month….

Things have changed, haven’t they? We have all been through

some stuff…

I have tried, on more than one occasion to get a post up,

but they all just seemed so…depressing.

But, time passes and hopefully we have learned a few things

to better prepare us...

Prepare us for things like, oh, I don’t know…making a new

sail…???

2019 saw our old sailboat die a sudden death by broken mast,

aided by 40 years of poor upkeep compounded by rotting would and some really

good wind. We were rail in the water when we heard the CRACK. Initially

assuming it was all our stuff flying to the leeward side. Instead, that horrible sound turned out to be

one of the mast stays, which had pulled free of the interior anchor thus

leaving the mast partially unsupported. I dropped the mainsail as Rob started

the engine and we cautiously motored back to dock at 5mph. All the time

discussing how we were going to fix the problem. Once docked, it become clear

that the best way to fix the problem, short of sinking the boat in a hidden cove,

was to somehow donate the boat.

|

| this is not a good thing |

As luck would have

it, the marina Cool Change lived at was run by a sailboat lover and they worked

out a deal to just take the boat, and it’s brand new outboard, off our hands.

We decided then that our little 15ft wooden boat would do

from here on out.

We decided that we would not buy another boat.

So, two years later, we bought a BIGGER boat….

Meet St. Frank, a 27ft, 35ish year old Catalina tall-rig.

(this last descriptor becomes way more important than I thought it would…)

St Frank – formerly/currently/actually – named St Frances by

her previous owner, will be eventually undergoing a name change. (Can a boat be

gender fluid?) Not that we have anything against St. Frances – I have known two

very lovely women named Fran. But St Frances is just not a name that fits us.

Once we land on a name fitting to all three of us – Rob, me and the boat –

there will be a renaming ceremony. I can’t risk angering Neptune any more than

I already have.

St Frank has it all, her previous owner outfitting the cozy sloop

with a microwave, a portable electric refrigerator, a sound system and an AIR

CONDITIONER!! We have seat cushions, kitchenware, movable cupholders and no

jib. (The jib is the smaller, front sail on a sloop. It helps balance the larger main sail and just makes the whole boat so pretty.)

|

| an actual galley |

|

| AND no more leaking port-a-potty! |

What the boat does have is a storm sail, which is a much smaller

front sail for inclement weather and a Genoa.

|

| the large sail at the bow is the Genoa, note how much small the actual main sail is |

A Genoa is an ENOURMOUS front

sail which grabs every ounce of wind there is allowing for some fast racing, if

you are so inclined, and a lot of heeling. (Where the side of the boat leans

into the water, which is fun, but the exact opposite of relaxing which is

always my goal when on a boat.)

Which brings me to the theme of the next few posts (yes,

there will be more!)

Because sails are expensive and we have already spent our

Not Buying Another Boat budget on the above said boat, AND because I have made

two other sails, it was decided that we would order one more sail kit from

Sailrite.

The two previous sails were also Sailrite kits – precut sail

pieces, hardware and some really helpful directions and diagrams. These sails were

for our wooden boat. Because if Rob could make the entire boat of wood, just

think how cool it would be if I made the sails…

Anyway, it was definitely a learning curve. But it has been

15 years since I made those sails and apparently 15 years is exactly how long

it takes for me to forget what a semi-complicated and awkward process sail

making is on a portable home sewing machine.

Sails these days are made of dacron – what can only be

described as plastic paper fabric. It is stiff when new but over time softens

to an almost leather feel. And it makes a cool popping sound as the needle pierces

it.

The mast for this new/old boat is 30ish feet tall, which

calls for a rather big sail. However, all I heard when discussing this project

was ‘jib’ and ‘it’s a smaller sail than the main’.

I have no concept of size, or distance. All I knew was the

last jib I made was not enormous.

I am pretty sure my judgement was impaired by a tasty rum

drink.

Turns out the small sail for a 27ft boat is quite a bit

larger than the big sail for a 15ft boat.

Huh.

The sail comes precut in sections. The process involves

sewing sections together and then sewing these sections to the other sections

until you have an entire sail. The idea is to keep the sections a manageable size.

Which in theory makes sense, if you have a football field size work room with a

table of the same dimensions.

|

| hardware with candles... |

|

why a pic of an enormous bottle of wine?

because this is what I will be drinking once this project is finished |

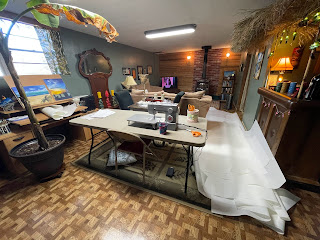

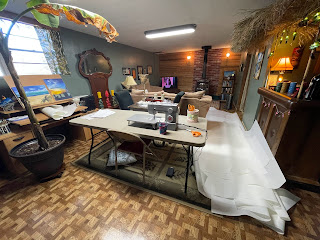

I have two folding banquet tables, in a fully furnished

basement family room that also currently houses a banana tree waiting for above

40 degree weather outside.

This is what that set-up looks like:

|

| see all that white stuff on the floor? those are the PIECES of the sail |

At this posting, the sail is about a third of the way

finished.

Upcoming posts will discuss the finer points of securing,

rolling and wrangling dacron, repetitive bobbin winding and needle threading

and dealing with the panic of thinking you have sewn everything backwards……

Until next time...

|

this.

this is what makes all the broken needles worthwhile |